| Availability: | |

|---|---|

| Quantity: | |

The heat-sensitive layer is formulated using the latest technology to provide enhanced sensitivity and a wider temperature range for printing. This ensures that the labels can be printed accurately even on older or less precise thermal printers. The adhesive used in our thermal labels is a high-tack, pressure-sensitive adhesive that provides immediate adhesion upon contact with the surface. It is also designed to have a long-term holding power, preventing the labels from falling off over time.

The label construction also includes a release liner that is easy to remove, allowing for quick and hassle-free application. The liner is coated with a special silicone layer to ensure smooth separation from the label without leaving any residue on the adhesive side.

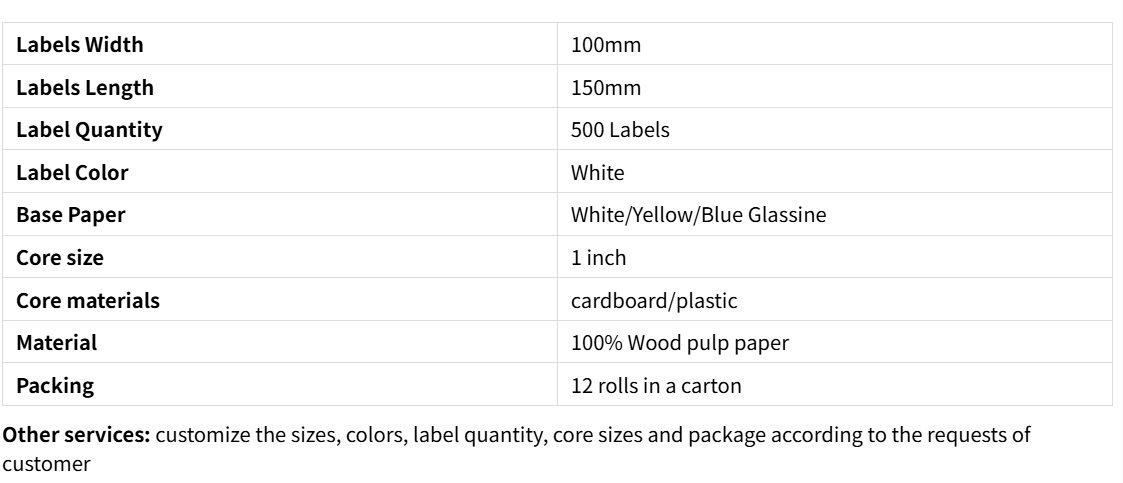

Versatile application: 100x150 mm thermal label rolls are suitable for a wide range of industries and applications, from small businesses to large corporations. Whether it's for labeling products, packaging, or assets, our thermal labels can meet the diverse needs of our customers.

Cost-Effective & Time-Saving: As a direct thermal solution, it bypasses the expense of toner or ribbons, reducing operational costs. The self-adhesive backing allows for quick application, speeding up labeling tasks in logistics, retail, or warehousing.

High Compatibility & Convenience: The 100x150mm direct thermal label roll is designed for seamless integration with most thermal printers, eliminating the need for ink or ribbons. Its compact size (100mm width x 150mm length) is ideal for shipping labels, barcodes, and inventory tags, ensuring efficient printing without extra setup.

.

In the manufacturing industry, thermal labels are used for product identification, quality control, and traceability. They can be printed with product specifications, serial numbers, and manufacturing dates, allowing for easy tracking and management of products throughout the production process.

In the food and beverage industry, thermal labels are essential for labeling products with ingredients, nutritional information, and expiration dates. The labels need to be resistant to moisture and temperature changes to ensure the safety and quality of the food products.

In the electronics industry, thermal labels are used for labeling components, circuit boards, and electronic devices. The labels need to be able to withstand high temperatures and chemical cleaning processes without peeling or losing their print quality.

Printer Compatibility Check:

Ensure that your thermal printer supports label rolls measuring 100 x 150 mm (width x length). Adjust the printer settings to match the label size before use to ensure accurate printing.

Loading the Label Roll:

Open the printer cover and insert the roll onto the spindle with the label side facing outward (thermal coating toward the print head).

Feed the label edge through the guide, then close the cover.

Perform a test print to confirm alignment and clarity.

Optimal Printing & Handling:

Use direct thermal-compatible software (e.g., Bartender, NiceLabel) for barcode/shipping labels.

Avoid exposing labels to heat, sunlight, or friction to prevent premature fading.

Peel and apply labels smoothly.

Q: What is the MOQ for 100 x 150mm thermal label rolls, 500 labels per roll?

A: In general, it is 500 rolls. When the purchase quantity is less than 500 rolls, the price will be higher than before.. If you can accept the price, we can also work together.

Q: Can I preprint the logo on the 100 x 150mm thermal label rolls?

A: Yes, we can prepare the customization service. If you have the needs, please send us the logo design files and product pictures.

Q: What is the minimum order quantity for custom thermal labels?

A: The minimum order quantity for custom thermal labels may vary depending on the specific requirements of your order, such as label size, design complexity, and material type. Moreover, we strive to accommodate the needs of both small and large businesses, and we are willing to discuss your specific needs to find a suitable solution.

Q: If I pre-print logos on 100x150 mm thermal label rolls, how long will it take to produce the samples?

A: Production time depends on the complexity of the logo. Generally speaking, it takes about 20 days. If the logo is relatively complex, production time will be about 25 days.

Q: How to send samples and goods, and how long will it take to arrive?

A: We usually ship samples via DHL, UPS, FedEx or TNT, which typically takes 3-5 days to arrive. In most situations, goods are shipped by sea